In today’s fast-paced world, where every second counts and every detail matters, the need for precision is more important than ever. Whether it’s ensuring the smooth operation of manufacturing equipment or maintaining the accuracy of medical instruments, calibration plays a critical role. But what exactly is calibration, and why is it so crucial? How can accurate calibration boost operational efficiency across various industries? Let’s dive in to explore the answers to these questions and more.

Introduction to Calibration

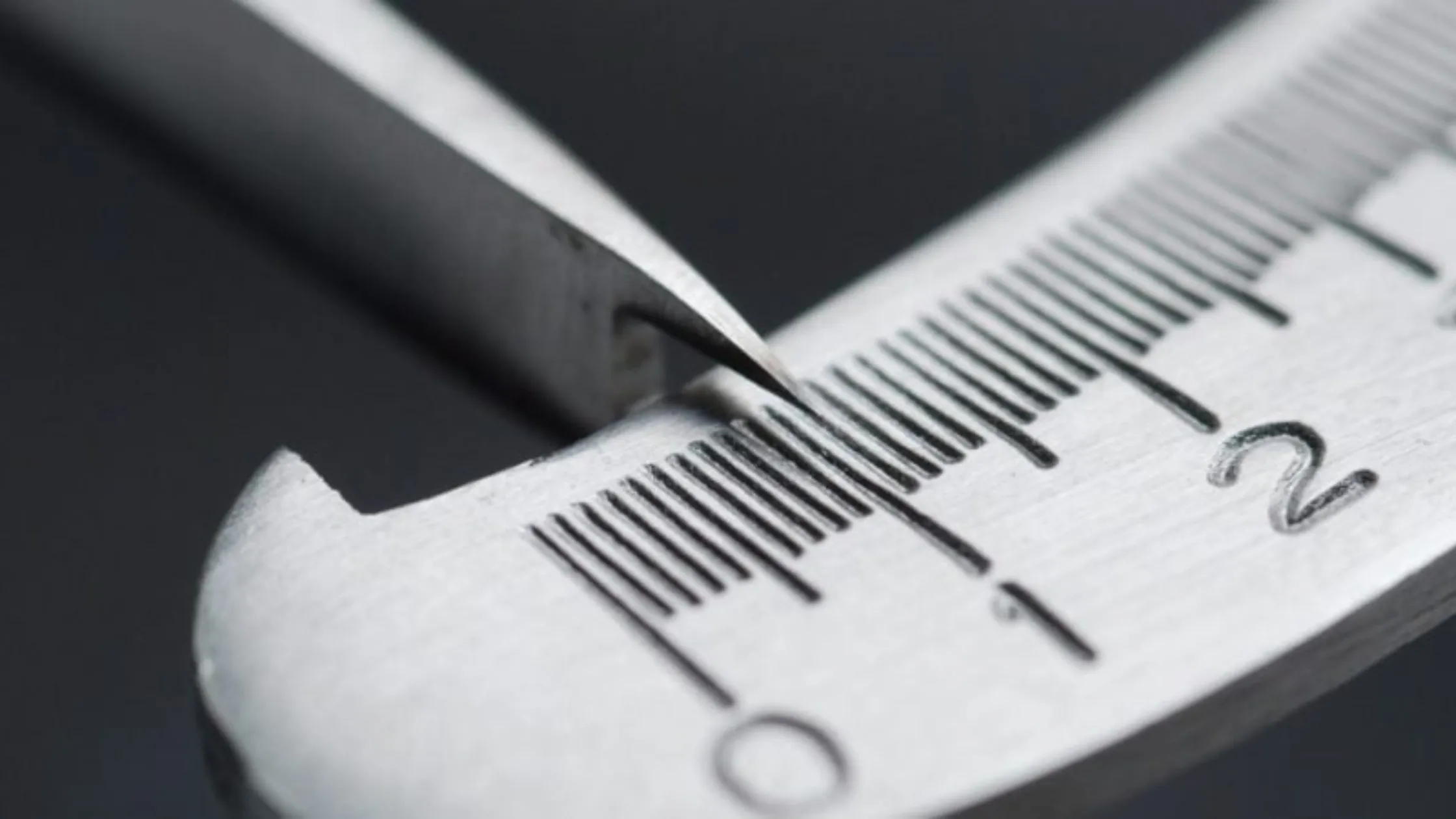

Calibration is the process of adjusting and fine-tuning equipment to ensure that it measures accurately. Imagine you’re trying to weigh something on a scale, but the scale is slightly off—your measurement wouldn’t be precise, and the outcome would be flawed. Calibration corrects such discrepancies, ensuring that equipment provides accurate and reliable results.

The Importance of Accuracy

Why does accuracy in calibration matter so much? In many industries, even the smallest margin of error can lead to significant problems. For instance, a slight deviation in the calibration of a pharmaceutical machine could result in a batch of medicine being ineffective or, worse, harmful. Accuracy in calibration ensures that equipment operates within specified limits, maintaining consistency and reliability in processes.

How Calibration Affects Different Industries

Calibration isn’t a one-size-fits-all process. Different industries require different levels of precision, and the impact of accurate calibration can vary. Let’s explore how calibration plays a vital role in several key industries.

The Role of Calibration in Manufacturing

In manufacturing, calibration ensures that machines operate correctly, producing products that meet quality standards. A machine that’s not properly calibrated could produce parts that don’t fit together correctly, leading to defects and wasted materials. Accurate calibration helps maintain efficiency by reducing downtime and preventing costly errors.

Precision in Healthcare: A Matter of Life and Death

In healthcare, the stakes are even higher. Medical devices like blood pressure monitors, thermometers, and imaging equipment must be accurately calibrated to provide correct readings. Inaccurate calibration in this context isn’t just inconvenient—it can be dangerous, potentially leading to misdiagnosis or improper treatment.

Calibration in the Aerospace Industry

The aerospace industry is another sector where precision is paramount. Aircraft rely on numerous calibrated instruments to ensure safe and efficient operation. A miscalibrated altimeter, for instance, could lead to incorrect altitude readings, putting the aircraft and its passengers at risk. Accurate calibration in this industry ensures safety and compliance with stringent regulatory standards.

How Accurate Calibration Saves Costs

Accurate calibration isn’t just about preventing disasters; it’s also about saving money. When equipment is calibrated correctly, it operates more efficiently, using resources more effectively. This leads to reduced waste, lower energy consumption, and longer equipment lifespan—all of which translate to cost savings for businesses.

The Impact of Inaccurate Calibration

What happens when calibration is neglected or done incorrectly? The consequences can be severe. Inaccurate calibration can lead to product recalls, legal liabilities, and reputational damage. It can also result in operational inefficiencies, with machines producing subpar products or requiring frequent maintenance. In short, the cost of inaccurate calibration can far outweigh the investment needed to maintain accurate calibration.

Ensuring Quality Control Through Calibration

Quality control is a cornerstone of any successful business, and calibration plays a key role in ensuring it. By regularly calibrating equipment, companies can maintain consistent product quality, meeting customer expectations and complying with industry standards. Accurate calibration also enables businesses to identify and address potential issues before they escalate into major problems.

The Future of Calibration Technology

As technology advances, so too does the field of calibration. Innovations such as automated calibration systems, real-time monitoring, and advanced sensors are making it easier than ever to maintain accurate calibration. These advancements not only improve precision but also reduce the time and effort required to perform calibration, further boosting operational efficiency.

How to Maintain Accurate Calibration

Maintaining accurate calibration is an ongoing process. It involves regular checks, adjustments, and documentation. Companies must establish a calibration schedule, train employees on proper calibration procedures, and invest in high-quality calibration equipment. By taking these steps, businesses can ensure that their equipment remains accurate and reliable, supporting long-term operational efficiency.

Conclusion: The Bigger Picture

Accurate calibration is more than just a technical requirement; it’s a critical component of operational efficiency. From manufacturing to healthcare to aerospace, the benefits of precise calibration are clear: improved quality, enhanced safety, reduced costs, and increased reliability. By prioritising calibration, businesses can achieve greater success and maintain a competitive edge in their respective industries.

FAQs

1. What is calibration, and why is it important?

Calibration is the process of adjusting equipment to ensure accurate measurements. It’s essential because it ensures that machines operate within specified limits, maintaining consistency and reliability.

2. How often should equipment be calibrated?

The frequency of calibration depends on the equipment and industry standards. Regular calibration is recommended, with schedules determined by factors such as usage, environment, and manufacturer guidelines.

3. What are the risks of not calibrating equipment?

Inaccurate calibration can lead to product defects, safety hazards, legal liabilities, and increased operational costs. It can also damage a company’s reputation and result in costly recalls.

4. How does calibration impact operational efficiency?

Accurate calibration ensures that equipment operates efficiently, reducing waste, downtime, and maintenance costs. It also supports consistent product quality, enhancing overall operational efficiency.

5. What are the latest trends in calibration technology?

Advancements in calibration technology include automated systems, real-time monitoring, and advanced sensors. These innovations improve accuracy and efficiency, making it easier to maintain precise calibration.